| Brand Name | NA |

| Model Number | 816301 |

| Certification | Mixer compliance with KTW,WRAS,ACS |

| Surface Finishing | Chrome |

| Connection | G1/2 |

| Function | Mixer: hand shower, head shower, tub spoutHand shower: inner spray, outer spray, full spray |

| Materia | Zinc/ Stainless steel/ Plastic |

| Nozzles | Self-cleaning TPR nozzle |

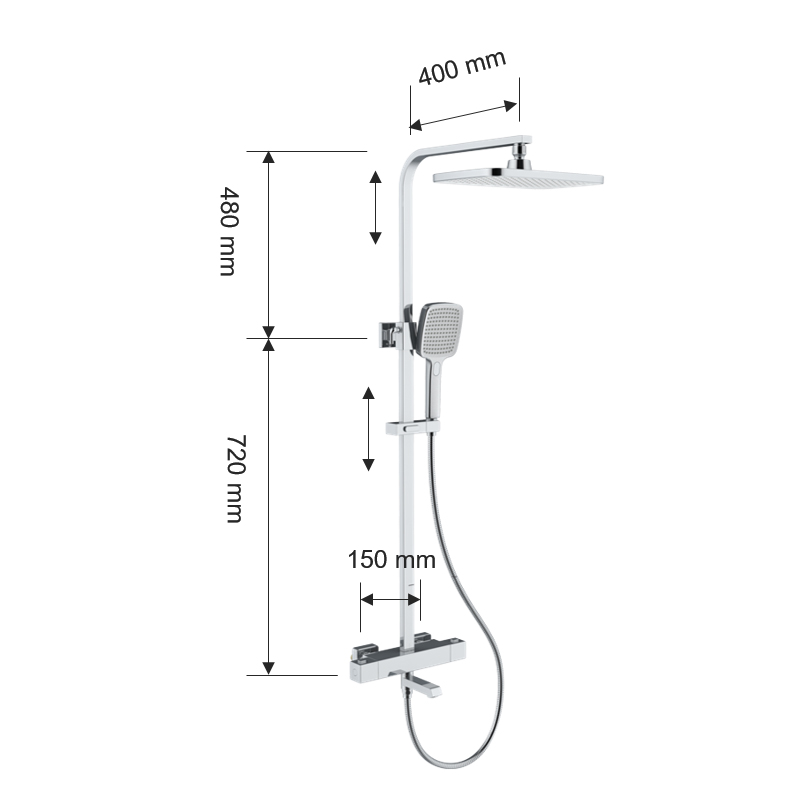

| Faceplate Diameter | Mixer dia: φ42mm, hand shower size:110x266mm, head shower: 200x300mm |